Flextur Features Factory Solutions Including Innovative Fixturing at Fabtech, 2024

Dalton, OH – Flextur, a leading innovator in welding and workstation products designed to increase productivity while supporting 5S & LEAN initiatives, featured factory solutions at their booth, centered around their industry-changing Quick-Change Fixture Table for Cobot welding.

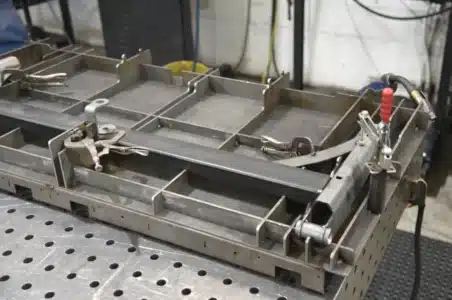

Flextur first presented their Quick-Change Fixture Tables at Fabtech last year. Since then, several companies, including Modine, have adopted Flextur’s innovative, cost-effective fixtures with unprecedented results.

Flextur displayed several fixture samples to support their new fixture-building initiative. With just a few simple steps and utilizing your parts, Flextur provides fixture solutions for you, whether or not you are a Cobot Quick-Change Table customer.

To meet you wherever you are on your welding automation journey, Flextur introduced their new Cobot Pedestal and Cart. Designed to adjust and attach to any welding table, this new pedestal saves valuable table space and increases accuracy at an affordable price point. This is an excellent entry point for anyone considering a Cobot who may not be ready for a full docking station and multi-table work cell.

In support of the Quick-Change Fixture Tables and fixture solutions, Flextur displayed its Fixture Storage Rack. This forkable, stackable rack is designed to hold 36” x 36” and 36” x 72” fixture plates, including fixtures of varying heights. This factory solution allows you to safely store fixtures near your Cobot cell or move fixtures in and out of the Cobot area based on the current job.

Additional innovations from Flextur included a new smaller welding curtain design specifically for pin and clamp tabletop use or in conjunction with the Flextur Quick-Change Fixture Tables. This curtain protects operators when performing a side-by-side operation and addresses the growing concern around Cobot welding safety regarding weld flash when loading and unloading parts.

Mobile tool board solutions for PPE and 5S events were on display along with standard and custom material handling solutions.

About Flextur

Flextur is a US manufacturer of welding and work cell products designed to increase productivity while supporting 5S & LEAN initiatives. Flextur products provide standardization, organization and increased efficiency from individual workspaces to factory solutions. Products include Cobot welding solutions, fixtures, welding tables, tool board solutions, material handling solutions, workbenches, pack stations and more. All designed to reduce cost, improve productivity and ensure compliance with safety and quality standards.

For more information, visit www.Flextur.com or contact Flextur at 877-435-3988 or connect@Flextur.com