How Chief Industries Enhanced Efficiency with Flextur’s Modular Cobot Welding Tables

Optimizing Robotic Welding Efficiency with Modular Workstations

Chief Industries, a diversified leader in metal building manufacturing, steel fabrication, commercial construction, agriculture, transportation, factory-built housing, and ethanol, continually seeks ways to improve efficiency and automation. Within its Chief Fabrication division, the engineering team faced a common industry challenge—maximizing the efficiency of robotic welding cells while maintaining flexibility in production workflows.

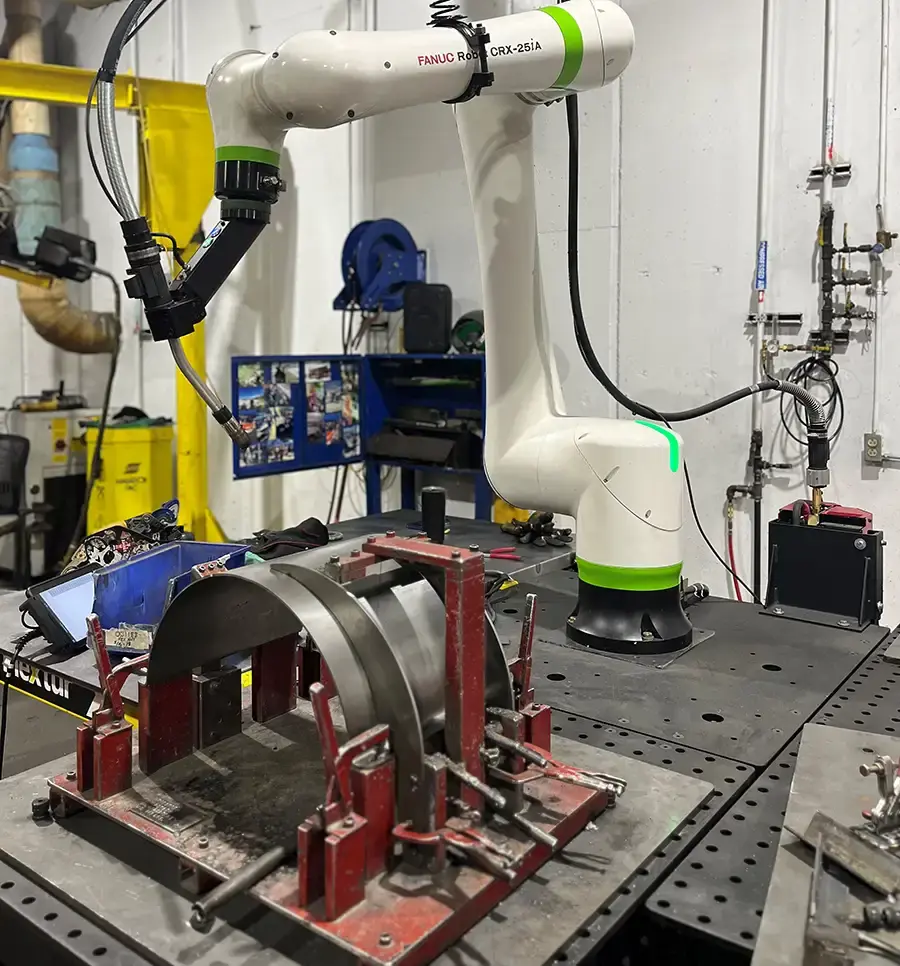

To overcome long setup times, fixture positioning challenges, and a lack of modularity, Chief Fabrication turned to Flextur’s Cobot Quick-Change Welding Tables, designed to improve precision, adaptability, and overall productivity in welding environments.

The Challenge: Improving Robotic Welding Efficiency

As robotic welding continues to transform manufacturing, companies must optimize supporting infrastructure for maximum productivity. Chief Fabrication identified several critical pain points in their existing processes:

- Extended setup times delaying production and increasing downtime.

- Locating and fixture positioning challenges, reducing accuracy and repeatability.

- Lack of modularity, making workflow adjustments difficult.

“The challenge of becoming more efficient with robotics and harnessing the latest technology to move our business forward is one of our core considerations,” said Tim Tietjen, Engineering Services Manager at Chief Fabrication. “When we began our project development into our cobot cell, we needed a flexible and repeatable table solution that accommodated our workflow with modular capability. The Flextur tables for cobot applications stood out right away in that regard.”

The Solution: Flextur Cobot Quick-Change Welding Tables

After thorough research and discussions with a distributor, Chief Fabrication selected Flextur’s modular cobot welding tables for their quick-change capability, adaptability, and precision engineering.

“With the understanding that most of our weld fixtures are dedicated tools, we needed a robust and efficient way to position the fixtures in relation to the cobot,” Tim Tietjen explained. “Flexibility was a concern, and the modularity of the Flextur robotic tables addressed that need.”

Why Flextur’s Cobot Quick-Change Welding?

Several key factors set Flextur’s cobot welding tables apart from other options:

- Modular and Adaptable Design – Easily configurable for different welding applications and robotic work cells.

- Quick-Change Capability – Reduces setup time significantly, improving production efficiency.

- Precision Engineering – Ensures repeatability, accuracy, and high-quality welds for small- and large-scale manufacturing.

- Scalability – Adjustable configurations support evolving manufacturing needs.

“The Cobot Quick-Change Welding Table allows for faster setups and gets parts online faster. This has been the most popular aspect I get feedback on from the people actually using it.”

The Results: Faster Setups, Increased Productivity, and Future Scalability

Since implementing Flextur’s Cobot Quick-Change Welding Tables, Chief Fabrication has seen substantial time savings, improved workflow efficiency, and reduced production lead times.

“The reduced setup time has been a big improvement. A lot of our customer parts are smaller lot sizes, and being able to speed up the setup time means we can get into production faster and reduce lead times.”

Beyond immediate efficiency gains, this project has also set the stage for future robotic automation initiatives.

A Strong Partnership: Engineering Support & Customer Service

Chief Fabrication emphasized the importance of customer service and engineering support in choosing Flextur.

“In this day and age of customer support, the value that Flextur provides by simply answering the phone and being ready with engineering support as challenges arise cannot be overstated. Flextur was ready when I needed them to answer and execute on a number of requests.”

Future Collaboration & Ongoing Automation Initiatives

Looking ahead, Chief Fabrication anticipates continued collaboration with Flextur as they explore new automation projects and process improvements.

“As we continue to look at new projects and development ideas, the Flextur team was helpful in a collaborative sense and flexible to our requests.”

Advice for Manufacturers Considering Modular Welding Solutions

For companies evaluating robotic welding tables or modular workstation solutions, Chief Fabrication offers this advice:

“Having a good understanding of your product workflow and the key characteristics that are holding you back is fundamental to understanding what technological improvements will provide the best return and biggest impact.”

Read the Full Case Study

See how Chief Industries optimized robotic welding with Flextur’s Cobot Quick-Change Welding Tables. Download the full case study here.