Home »

Flextur – Designed to Create an Efficient & Productive Lean Workflow

What is 5S

Organize Spaces so Work is Performed Efficiently, Effectively, and Safely

The first step to a successful Lean Journey begins with 5S implementation. 5S is a great tool for workplace organization and separates the tasks in bite size pieces. The term 5S stands for Sort, Straighten, Shine, Standardize and Sustain.

To separate and scrap anything that is not absolutely necessary for your production system. Continue sorting until you have only the items you use to add value to your product.

Every tool should have a place where it belongs. It should be in its place or in your hand. A place for everything and everything in its place.

Clean your work area. Eliminate causes of dirt. Maybe you can add some paint or light to make waste more visible. This will increase safety and create a more pleasant work environment.

Develop a standard process for routine jobs. The same job should be done the same way every time – no matter who is doing it. Standardizing prevents defects and lost time.

Train, train, and train some more. This is the hardest part of 5S. Continue doing the previous four elements as part of your culture.

What is Lean

Maximize Productivity While Reducing Waste Withing Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system and response times from suppliers and customers.

Empowering people is fundamental to the Lean process. Incorporating Flextur Lean and 5S workstations into your facility will help to empower your employees to be more organized and provide an efficient method to eliminate wasteful activities such as time spent searching for tools, materials, or supplies.

Downtime - The 9 Categories of Waste

Finished good fails to meet customer or QC expectations.

Producing more finished goods than required.

Time wasted for information, instructions, material, or equipment.

Human potential, underutilizing capabilities and delegating of tasks to individuals with inadequate training.

Excess product handling creates unnecessary use of people, tools, and equipment.

Too much inventory or materials – time to completion and capital restraints.

Time and effort wasted of people, and equipment or machinery.

More work, components and steps than what is required.

There are some things that are our of your control. Attitude is not one of them, and having a good one is perhaps the best asset you can have as an employee.

Learn How Lean And 5S Work Cells Will Drive Efficiency And Productivity

Decrease Wastes And Costs In Manufacturing Facilities

Did you know continuous improvement work cells deliver revenue growth? Lean and 5S work cells will drive efficiency and productivity and decrease waste and costs. This ebook will guide you through what Lean and 5S is and how it benefits you and your organization.

Benefits of Flextur Metal Pegboard / Tool Board

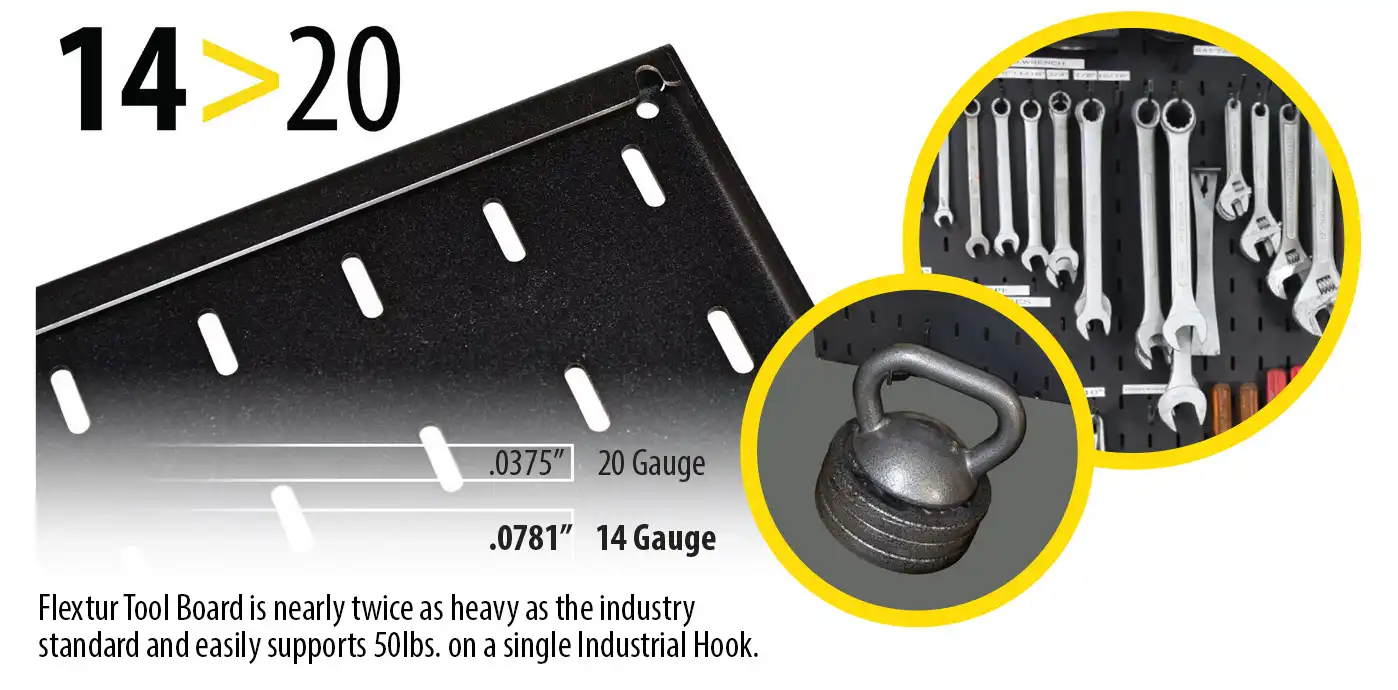

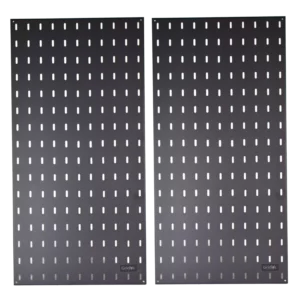

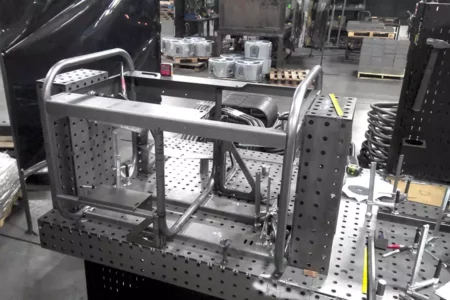

Flextur's Industrial Strength, 14-Gauge Steel Pegboards were engineered to solve for greater efficiency. Engineered to create a work cell with all your tools and materials within reach.

Industry’s strongest 14-Gauge Metal Pegboard – Nothing Compares

Patented design capable of holding 50lbs. on a single industrial hook

Available as Wall Mount Panels, Mobile Tool Board Workstations, and it’s available on all Flextur products

All Flextur accessories interlink for maximum flexibility and efficiency within personal workstations, departments, and entire facilities

Designed for Lean and 5S workflows

American Made in Dalton, Ohio U.S.A.