Organize & Standardize Your Facility

Outfit Your Facility For Maximum Productivity

As a manufacturing leader, you face many challenges such as labor shortages, skill gaps, production deadlines, and financial and quality goals. And an unorganized workplace causes excess waste of materials, motion, and time spent searching for lost or misplaced tools.

By organizing and standardizing your facility, you will decrease labor and material costs, improve product quality, and organize your tool and material storage while enhancing 5S, Lean, and OSHA compliance efforts providing a safer working environment for your employees and visitors.

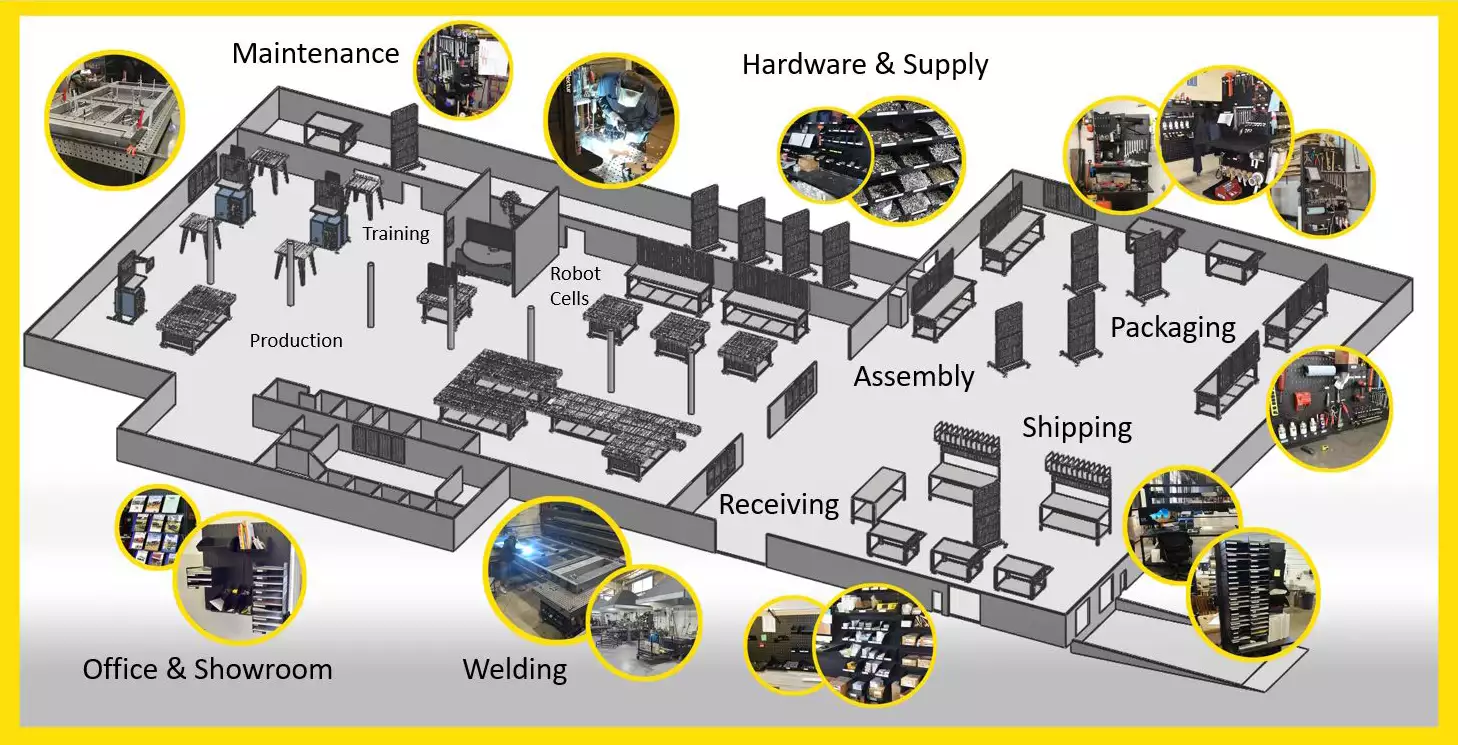

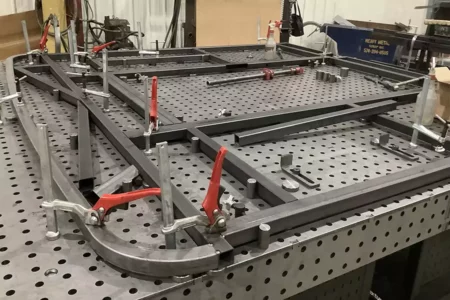

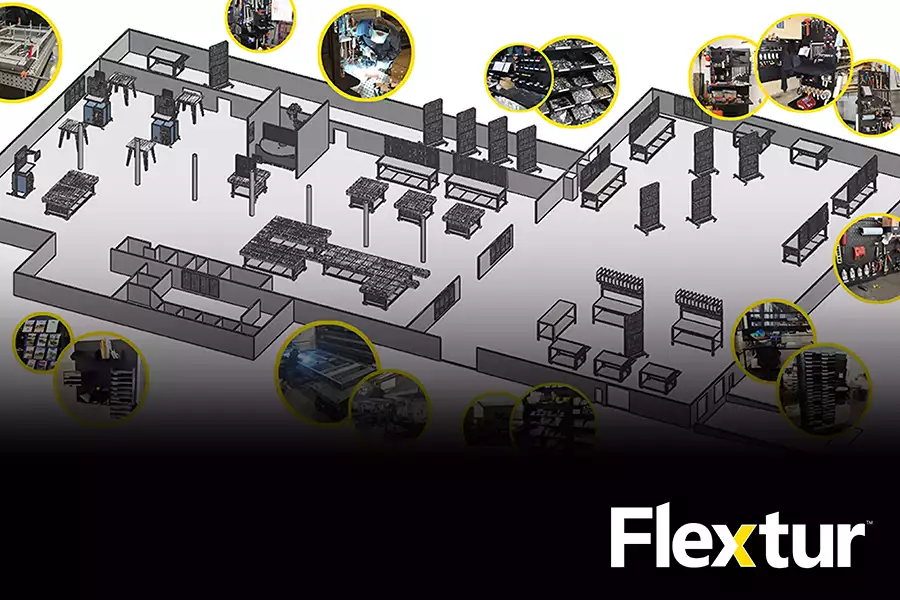

Flextur is equally capable in every department of your facility

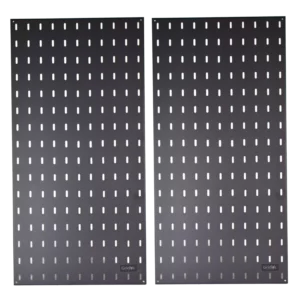

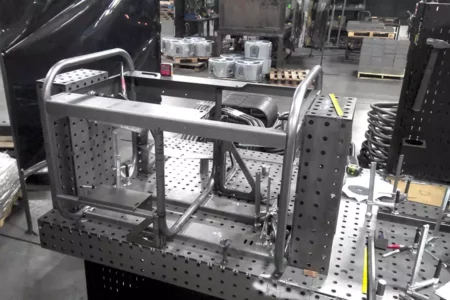

Engineered to solve unmet 5S and Lean workflow issues throughout your facility, Flextur products feature Gridlok Innovation and the Industry's Strongest and most versatile metal pegboard / tool board system. This system can improve efficiency in nearly every part of your business.

Top 6 Reasons to Interlink & Synchronize

Automate repetitive tasks

Reduce material waste

Improve workplace safety

Increase shop effeciency

Standardize workflows

Tool organization

Home »

Imagine a Highly Adaptable Yet Standardized Solution for Your Entire Facility

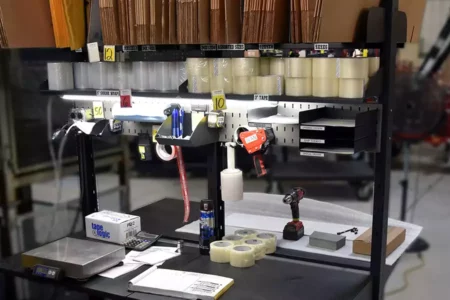

Using Flextur's standard off-the-shelf products and accessories throughout your facility allows you to create a highly adaptable system that is easily personalized for every employee and their workstation. Easily repurpose your Flextur equipment as the needs of personnel, departments, and the facility change. These unrealized benefits are recognized as you pursue and implement LEAN and 5S principles within your facility with the help of highly agile, durable, flexible, Flextur Workstations.

Organizing and standardizing workstations with Flextur is the answer!

Reduce time spent during the design, build, and finishing steps resulting in shorter lead times, fewer back orders, and greater profitability. Integrating Flextur workstations into your facility will help reduce cycle times, maximize space, minimize waste, and create greater efficiencies while standardizing your workflow and reducing defects resulting in a better quality product that costs you less.