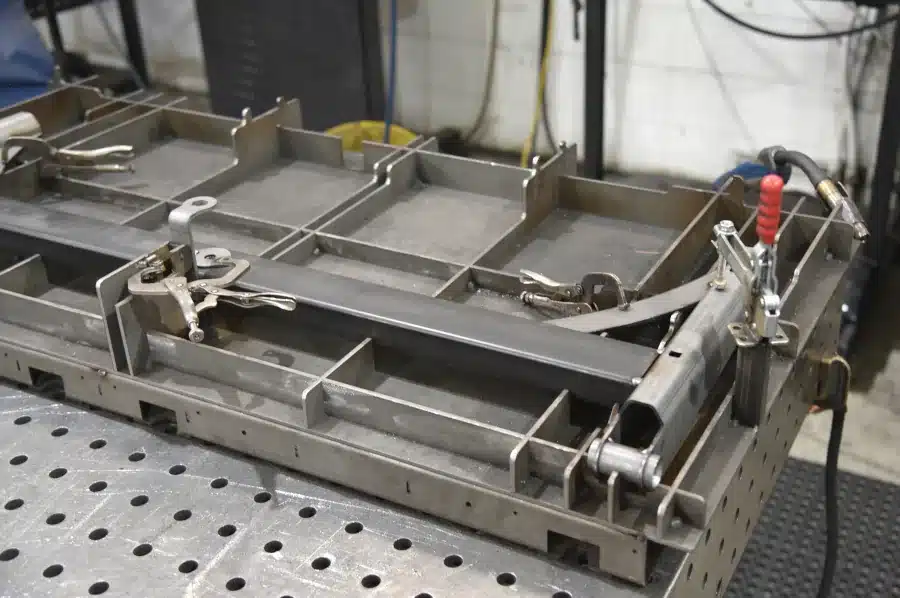

Flextur is Changing the Game with Innovative Fixture Solutions

Fixture faster, with less expense and greater flexibility

Fixtures are extremely expensive, difficult and time consuming to create, and essentially worthless if there is a sudden design change.

What if fixtures could be created quickly, affordably, and could be easily and cost effectively modified if something changes?

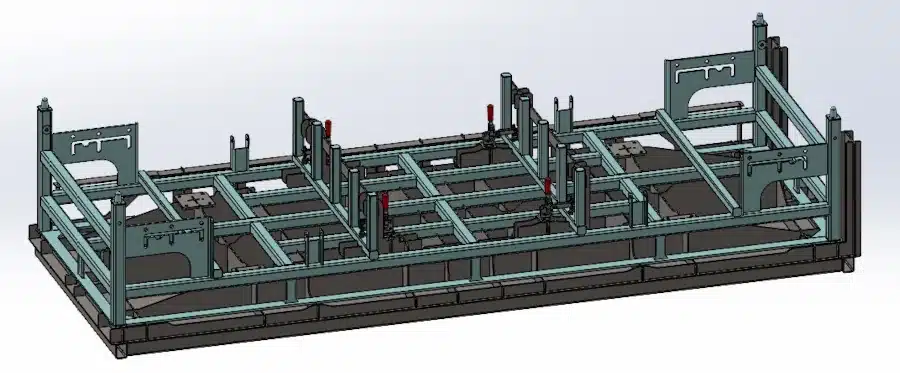

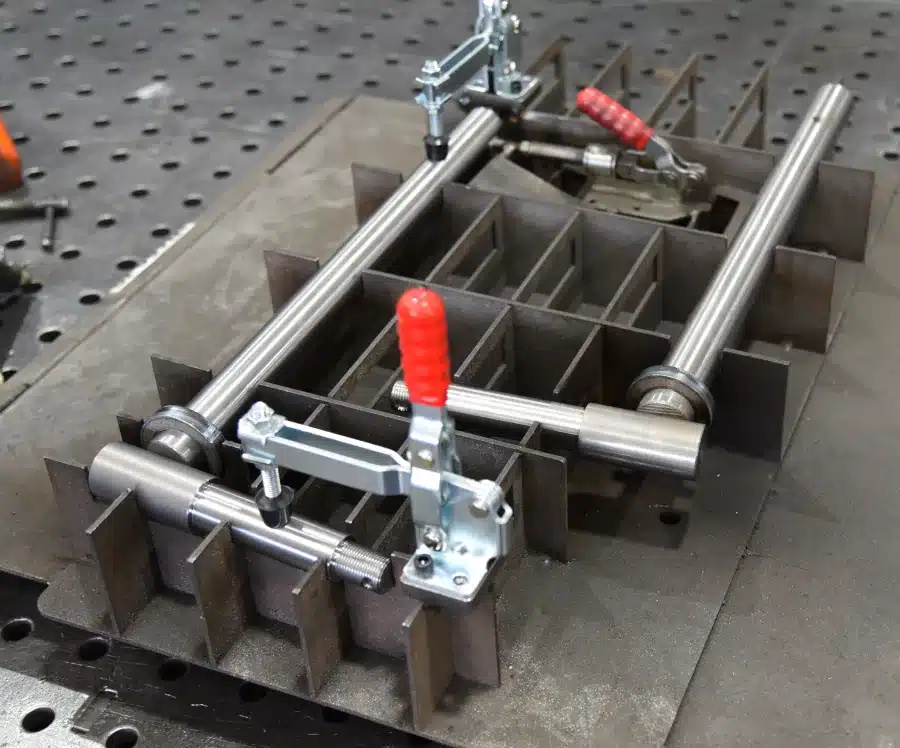

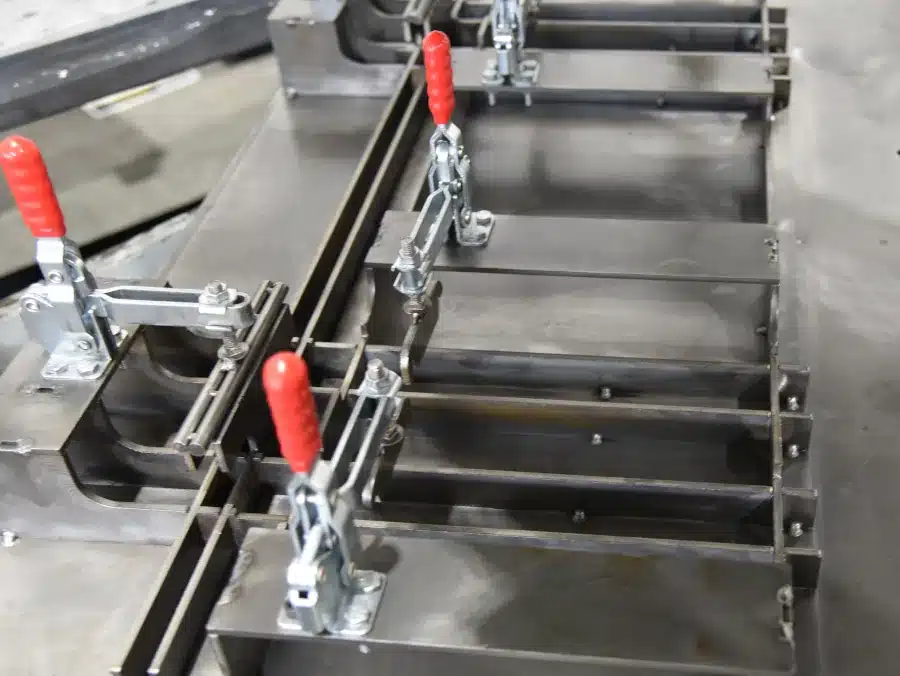

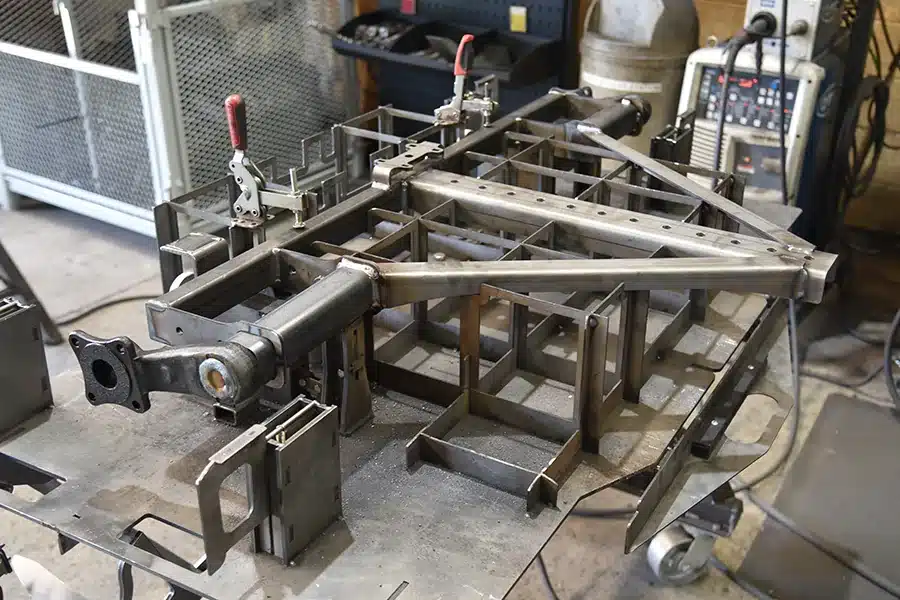

With Flextur, you can afford to create fixtures faster, with ROI’s that make sense. Even for low volume parts. Benefit right away from exacting repeatability, and noticeable improvements in speed, accuracy and quality. Flextur designs fixtures for both manual and automated welding, turntables, head and tail stocks and Flextur’s own Quick-Change Welding tables.

Many of our completed fixtures, including engineering and proofing time, sell for less than $3,000.

Flexturs process is well documented and communicated to our customers. And we encourage our customers to reach out at anytime if there is a question, concern, or new information to be considered.

The process is rather simple:

- Identify the Project/Part(s) High Level Objectives, and timeline

- Customer provides STEP files once a simple NDA is executed

- Budgetary numbers are presented and approved

- Customer provides sample part(s) for baseline measurements and to set tolerances

- Fixture design drawing is reviewed and approved

- Fixture is built and tested at Flextur prior to delivery

- Fixture and all test parts are shipped to the customer