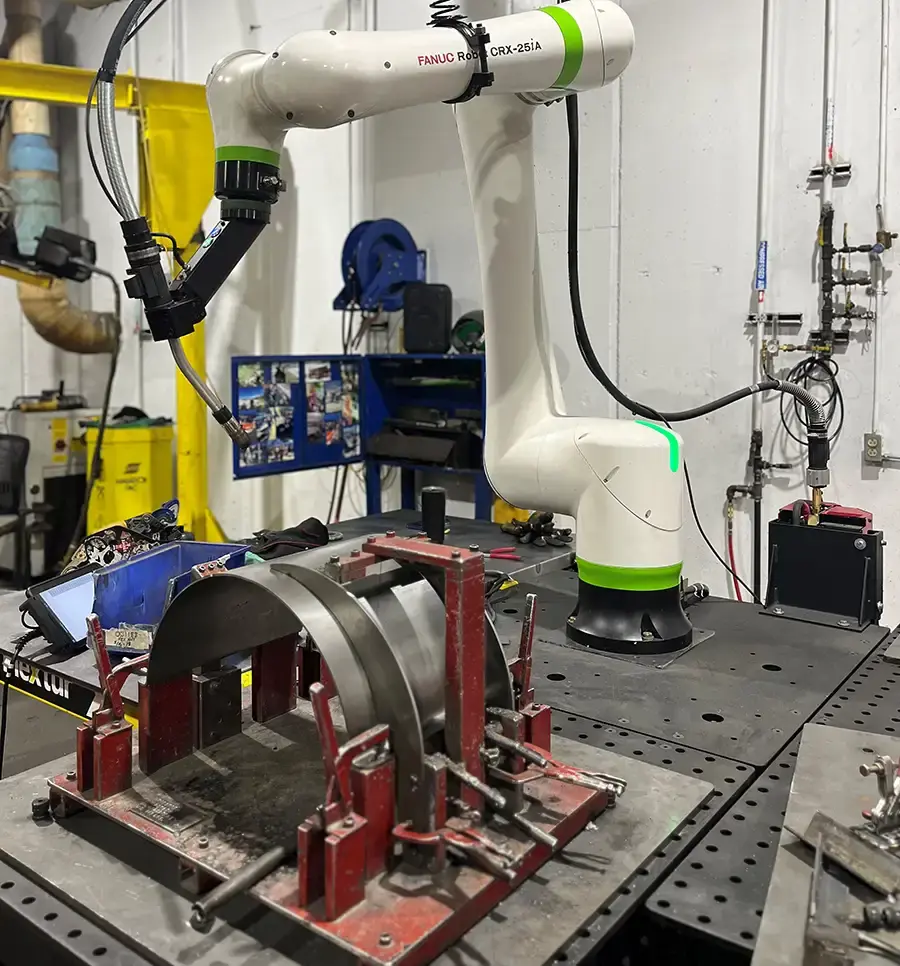

Chief Fabrication Improves Efficiency with Flextur’s Modular Cobot Tables

Overview: Chief Fabrication, a division of Chief Industries, is committed to innovation and efficiency in manufacturing. As the company expanded its use of robotics and automation, it needed a flexible, repeatable workstation to streamline its cobot welding process.

Objective: Enhance efficiency, accuracy, and flexibility in robotic welding while reducing setup times and improving workflow adaptability.

Challenges: As Chief Fabrication expanded its use of robotics and automation, several inefficiencies became apparent. Extended setup times were causing production delays, making it difficult to maintain efficiency. Fixture positioning challenges impacted both accuracy and repeatability, leading to inconsistencies in the welding process. Additionally, existing workstation solutions lacked modularity, limiting flexibility and slowing down transitions between different production runs. To fully optimize its cobot welding operations, Chief Fabrication sought a versatile, repeatable welding table that could integrate with its workflow and adapt to changing production demands.

Solution: To address these challenges, Chief Fabrication implemented Flextur’s Cobot Quick-Change Welding Tables designed to support quick fixture adjustments and reduce downtime between production runs. The tables' quick-change fixture system allowed for more efficient setup times, while their adaptable design enabled flexibility in workflow configurations. With the ability to reposition and swap fixtures as needed, operators could transition between tasks more efficiently, improving overall productivity in the welding process.

Results: Since implementing Flextur’s solution, Chief Fabrication has achieved:

- Reduce setup times, increasing operational efficiency

- Faster production transitions, particularly for small-lot manufacturing

- Shortened lead times, enhancing customer service

The success of this project has also provided a scalable framework for future robotics and automation initiatives.

“Flextur’s Cobot solutions stand out because of its modular and adaptable approach to creating efficient, customizable workspaces. Their solutions allow us to tailor our environment to fit specific needs while optimizing workflow and productivity. Flextur’s products are versatile and easy to reconfigure, offering us the ability to change layouts quickly as the needs evolve.”

- Tim Tietjen, Engineering Service Manager at Chief Fabrication

Conclusion: Flextur’s Cobot Quick-Change Welding Tables transformed Chief Fabrication’s workflow, cutting setup times, enhancing flexibility, and boosting productivity. With these results, Chief Fabrication continues to explore automation opportunities with Flextur as a trusted manufacturing partner.